All Categories>

11

2024

-

10

How to Choose the Right Table-Type Cream Depositor for Your Needs

Classification:

【Summary description】How to Choose the Right Table-Type Cream Depositor for Your Needs In the competitive landscape of food and beverage manufacturing, having the right equipment is vital for success. Among the many essential machines in this industry, a **table-type cream depositor** plays a crucial role in ensuring precision and efficiency during production. This guide aims to provide comprehensive insights into sel

How to Choose the Right Table-Type Cream Depositor for Your Needs

In the competitive landscape of food and beverage manufacturing, having the right equipment is vital for success. Among the many essential machines in this industry, a **table-type cream depositor** plays a crucial role in ensuring precision and efficiency during production. This guide aims to provide comprehensive insights into selecting the best cream depositor tailored to your specific requirements.

Understanding Table-Type Cream Depositors

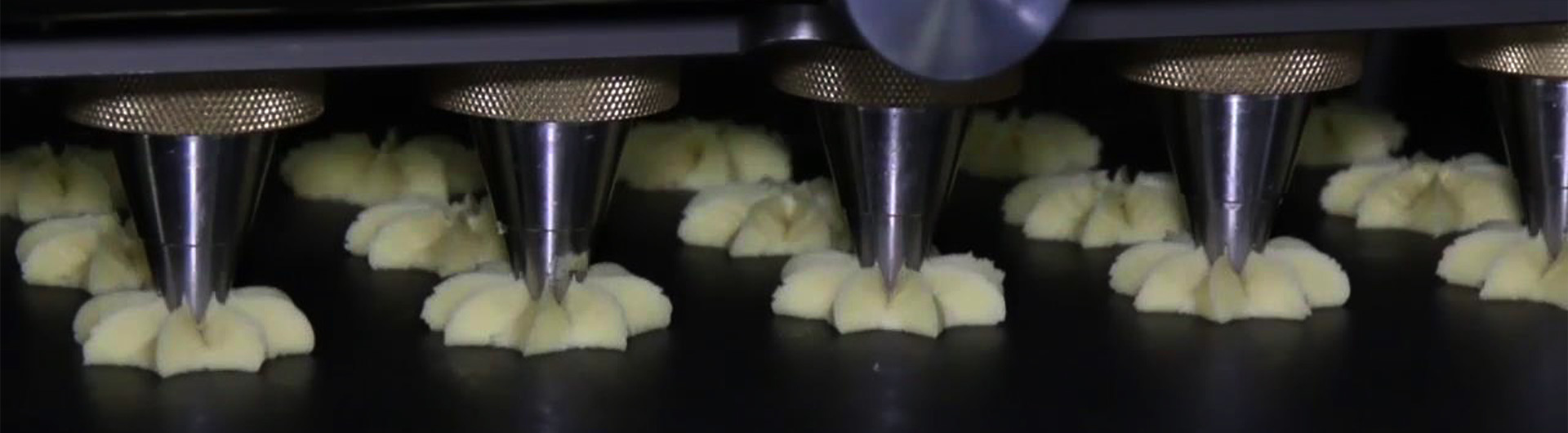

Before diving into the selection process, it is essential to understand what a table-type cream depositor is. This machine is designed to deposit cream and similar products in controlled amounts, making it ideal for various applications including cakes, pastries, and other confections.

Features of Table-Type Cream Depositors

Table-type cream depositors come equipped with various features that enhance their functionality. Some of the key features to consider include:

- **Adjustable Nozzles:** These allow for different sizes and shapes of cream deposits, giving you versatility in your production.

- **Digital Control Panels:** Modern depositors often feature digital controls, which provide precise adjustments for speed and volume.

- **Easy Cleaning Mechanisms:** Hygiene is paramount in food processing, so machines that are easy to disassemble and clean are essential.

- **Durable Construction:** Look for models made from high-quality materials that offer longevity and resistance to wear.

Key Considerations When Choosing a Cream Depositor

When selecting a table-type cream depositor, several factors should guide your decision-making process.

1. Production Capacity

Assess your production needs. If you’re operating a small bakery, a lower-capacity model may suffice. However, larger manufacturers may require high-capacity machines to keep pace with production demands.

2. Product Types

Different cream depositors are optimized for various products. Consider the specific types of cream, frosting, or other materials you will be depositing and ensure the machine you choose can handle them effectively.

3. Ease of Use

Select a model that is user-friendly, allowing your operators to quickly learn how to use it. Machines with intuitive controls and clear instructions can significantly reduce training time and minimize errors.

4. Maintenance and Support

Look for manufacturers that offer excellent after-sales support. A reliable service team can address maintenance needs quickly, minimizing downtime.

5. Budget Constraints

Establish a budget before beginning your search. While it is tempting to opt for the cheapest option, consider the long-term value and efficiency of higher-quality machines that may have a higher upfront cost but lower operational costs.

Comparing Different Models

Once you’ve narrowed down your criteria, it’s time to compare different models. In this section, we will discuss how to effectively evaluate different table-type cream depositors.

1. Read Reviews and Testimonials

Seek feedback from other users who have experience with the models you are considering. Online reviews, case studies, and testimonials can provide invaluable insights into the pros and cons of each machine.

2. Request Demonstrations

Whenever possible, arrange for product demonstrations. Seeing a machine in action can help you gauge its performance and suitability for your production needs.

3. Consider Energy Efficiency

Energy costs can significantly affect your bottom line. Look for depositors that offer energy-efficient features, which can help reduce overall operational costs.

4. Warranty and Guarantees

Check the warranty options available for each model. A longer warranty often reflects the manufacturer's confidence in their product and can provide peace of mind for your investment.

Integrating Your Cream Depositor into Your Production Line

After selecting the right table-type cream depositor, consider how it will fit into your existing production line.

1. Workflow Optimization

Evaluate your current workflow to identify where the cream depositor will best fit. Ensure that the machine’s placement allows for smooth transitions between different stages of production.

2. Training Your Staff

Invest time in training your staff on the proper operation and maintenance of the cream depositor. This will help to ensure that everyone is on the same page and can operate the equipment safely and efficiently.

3. Safety Protocols

Implement safety protocols to protect your employees. Ensure that all staff members are aware of emergency procedures and the importance of following operational guidelines.

FAQs About Table-Type Cream Depositors

1. What is a table-type cream depositor used for?

A table-type cream depositor is used for accurately depositing cream, frosting, and other similar products in controlled amounts for various food applications.

2. How do I maintain my cream depositor?

Regular cleaning, proper lubrication of moving parts, and routine checks of electrical components are essential for maintaining your cream depositor.

3. Can I use a cream depositor for other products?

Many cream depositors can handle a range of products, but you should check the specifications to ensure compatibility with your desired materials.

4. What should I look for in terms of warranty?

Look for a warranty that covers both parts and labor, ideally lasting at least one year, to protect your investment.

5. Are table-type cream depositors energy-efficient?

Many modern models are designed with energy efficiency in mind; however, it's essential to check the specifications for energy consumption ratings.

Conclusion

Choosing the right table-type cream depositor is a critical step in optimizing your food and beverage production processes. By considering factors such as production capacity, product types, ease of use, and maintenance, you can make an informed decision that suits your operational needs. Additionally, integrating the machine effectively into your existing workflow and training your staff will ensure that you achieve maximum efficiency and quality in your production line. In an industry where precision and reliability are paramount, investing in the right equipment can lead to increased productivity and customer satisfaction.

Previous article

The 23rd Bakery China will be rescheduled to April 27-30, 2021

Since its establishment in 1997, Bakery China has been committed to serving the whole industry chain in the baking industry and is a professional exhibition for bakery products manufacturing and services.

Nowadays, as China's economic development enters the new normal, the development of various industries in China are moving in the direction of intelligence and automation, which is extremely common especially in labor-intensive industries. As we all know, the goal of automation is to achieve the automatic management of processes, without the need for manpower, thereby reducing the cost of labor and greatly improving production capacity.

Five deficiencies and five trends in the development of my country's baking industry

my country's baking industry has emerged in the 1980s and has flourished since the 21st century. The categories are prosperous and the brands are emerging one after another. Common baked goods such as bread, cakes, biscuits and cookies have become popular choices for Chinese people for breakfast. So, what is the development status of my country's baking industry, and what is the future trend? Industry insiders pointed out that there are still "five deficiencies" in my country's baking industry, and the future development will show "five trends".