All Categories>

17

2024

-

10

Maximizing Efficiency: Unleashing the Power of Mousse Cake Mold Unloading for the Food and Beverage Industry

Classification:

【Summary description】Maximizing Efficiency: Unleashing the Power of Mousse Cake Mold Unloading Table of Contents Introduction to Mousse Cake Mold Unloading Importance of Efficient Mousse Cake Mold Unloading Challenges in Mousse Cake Mold Unloading Innovative Technologies in Mold Unloading Best Practices for Mousse Cake Mold Unloading Case Studies of Successful Implementations Impact of Eff

Maximizing Efficiency: Unleashing the Power of Mousse Cake Mold Unloading

Table of Contents

- Introduction to Mousse Cake Mold Unloading

- Importance of Efficient Mousse Cake Mold Unloading

- Challenges in Mousse Cake Mold Unloading

- Innovative Technologies in Mold Unloading

- Best Practices for Mousse Cake Mold Unloading

- Case Studies of Successful Implementations

- Impact of Efficient Unloading on Production

- Future Trends in Mousse Cake Production

- Conclusion

- Frequently Asked Questions

Introduction to Mousse Cake Mold Unloading

In the fast-paced world of food and beverage manufacturing, optimizing every aspect of the production line is critical to maintaining a competitive edge. **Mousse cake mold unloading** is a pivotal process that can significantly influence production efficiency, product quality, and operational costs. By enhancing the unloading process, manufacturers can not only reduce waste but also ensure that their mousse cakes maintain their exquisite texture and flavor.

This article delves into the intricacies of **mousse cake mold unloading**, exploring its importance, the challenges faced, and the technologies that can transform this essential process.

Importance of Efficient Mousse Cake Mold Unloading

Efficient unloading of mousse cake molds is crucial for several reasons:

1. Time Savings

Streamlining this process can reduce downtime on the production line. Faster unloading leads to quicker subsequent steps, allowing manufacturers to maximize their output.

2. Quality Assurance

Proper unloading techniques ensure that mousse cakes retain their shape and structural integrity, thus maintaining their quality. Any mishandling during this process can result in product defects, leading to customer dissatisfaction.

3. Cost Reduction

By minimizing waste and maximizing throughput, companies can reduce overall operational costs. Efficient unloading processes lead to fewer ingredients wasted and lower labor costs associated with handling defective products.

4. Enhanced Worker Safety

Efficient mold unloading systems can also improve worker safety. Automated systems reduce the risk of injury associated with manual unloading, allowing staff to focus on other important tasks.

Challenges in Mousse Cake Mold Unloading

While the benefits of efficient mold unloading are clear, various challenges can impede progress:

1. Manual Handling Issues

Manual unloading can lead to physical strain on workers and potential mishaps that can damage the mousse cakes. Finding a reliable solution to automate this process is essential.

2. Equipment Limitations

Many existing unloading systems may not be suitable for diverse mold shapes and sizes, which can constrain adaptability in production.

3. Product Consistency

Variability in the mousse cake itself can impact unloading efficiency. For instance, cakes that are too soft may break apart during unloading, necessitating a balance between recipe formulation and unloading techniques.

Innovative Technologies in Mold Unloading

To overcome these challenges, manufacturers are increasingly adopting **innovative technologies** that enhance the efficiency of mousse cake mold unloading:

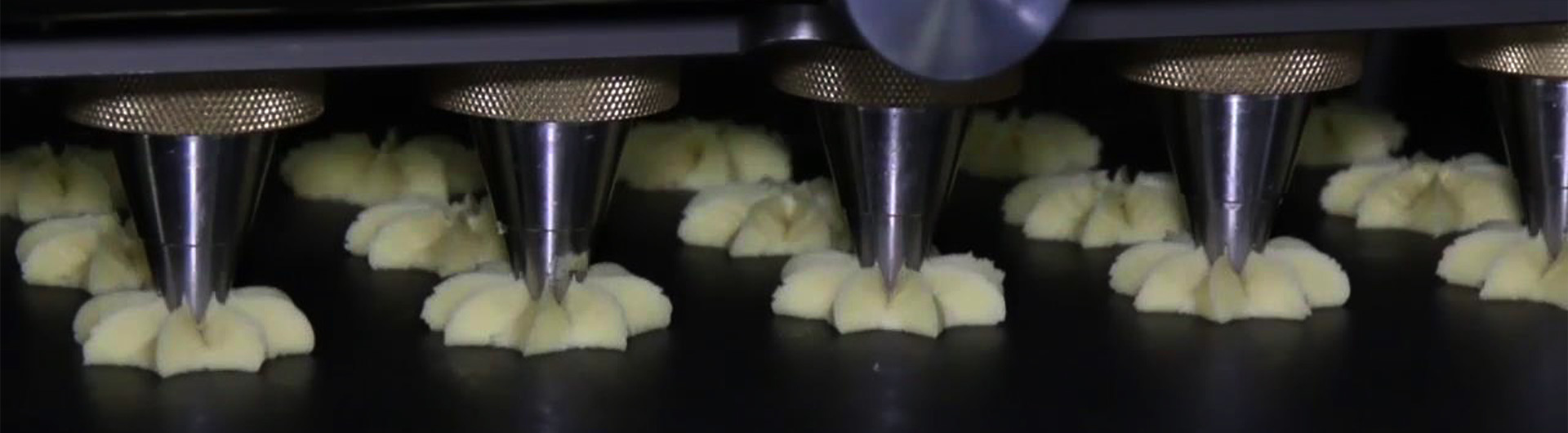

1. Automated Unloading Systems

Automation technology allows for precise control over the unloading process. Robotic arms and conveyors can handle molds gently, ensuring that mousse cakes are unloaded without damage.

2. Smart Sensors

Integrating smart sensors into the unloading process can provide real-time feedback on cake consistency and mold positioning, which can help in making immediate adjustments to the unloading procedure.

3. Heating and Cooling Mechanisms

Proper temperature regulation can facilitate easier mold release. Utilizing heating elements to warm molds slightly after cooling can create a more effective unloading environment.

4. Advanced Mold Design

Investing in molds designed specifically for easy release can significantly reduce the challenges associated with mold unloading. Non-stick coatings and flexible mold materials can minimize cake breakage.

Best Practices for Mousse Cake Mold Unloading

To maximize efficiency, manufacturers should consider the following best practices:

1. Regular Equipment Maintenance

Ensuring that unloading equipment is well-maintained prevents unexpected breakdowns that can halt production.

2. Staff Training

Educating staff on the latest unloading techniques and technologies can enhance overall efficiency and safety.

3. Workflow Optimization

Mapping out the unloading workflow to identify bottlenecks can lead to significant improvements in operational efficiency.

4. Continuous Improvement

Regularly reviewing unloading processes and gathering feedback from staff can help identify areas for improvement.

Case Studies of Successful Implementations

Several companies have successfully transformed their mousse cake mold unloading processes, resulting in impressive gains in efficiency and quality.

1. Company A: The Automation Revolution

Company A implemented a fully automated unloading system, resulting in a 30% increase in production speed and a drastic reduction in product defects. Their investment in robotic technology paid off significantly, demonstrating the value of automation in the food industry.

2. Company B: Temperature Control Success

Company B introduced advanced temperature regulation systems in their unloading process. This innovation minimized cake breakage and improved overall product quality, leading to higher customer satisfaction and retention rates.

Impact of Efficient Unloading on Production

The impact of improving mousse cake mold unloading extends beyond mere efficiency.

1. Market Competitiveness

With increased production speed and reduced costs, companies can offer competitive pricing while maintaining product quality. This can lead to greater market share and increased sales.

2. Sustainability

Efficient processes contribute to sustainability by reducing waste and energy consumption. Companies implementing these practices can enhance their corporate responsibility image.

3. Enhanced Customer Loyalty

By consistently delivering high-quality products, companies can foster customer loyalty, leading to repeat business and positive word-of-mouth referrals.

Future Trends in Mousse Cake Production

The future of mousse cake production looks promising, with several trends emerging:

1. Increased Automation

The food industry will likely see a surge in automation, with more sophisticated technologies being developed to handle complex tasks.

2. Eco-Friendly Practices

Sustainability will become a crucial aspect of production, with companies seeking eco-friendly materials and processes to attract environmentally conscious consumers.

3. Customization and Personalization

As consumer preferences shift towards personalized products, manufacturers will need to adapt their processes to offer customizable mousse cake options while maintaining efficiency.

Conclusion

Maximizing efficiency in mousse cake mold unloading is essential for food and beverage manufacturers aiming to improve their production processes. By embracing innovative technologies, adhering to best practices, and understanding the potential challenges, companies can unleash the true power of their production capabilities. The implications of efficient mold unloading extend beyond operational benefits, impacting product quality, customer satisfaction, and overall market competitiveness. As the industry evolves, staying ahead of trends and continuously improving will ensure lasting success.

Frequently Asked Questions

1. What is mousse cake mold unloading?

Mousse cake mold unloading is the process of removing mousse cakes from their molds after they have set, ensuring that the cakes retain their shape and quality.

2. Why is efficient unloading important?

Efficient unloading minimizes downtime, ensures product quality, reduces costs, and enhances worker safety.

3. What technologies can improve the unloading process?

Automated systems, smart sensors, advanced mold designs, and temperature control mechanisms can significantly enhance unloading efficiency.

4. How can companies overcome unloading challenges?

Implementing automated systems, providing staff training, and regularly maintaining equipment can help overcome common unloading challenges.

5. What future trends should we expect in mousse cake production?

Increased automation, eco-friendly practices, and customization options are emerging trends that will shape the future of mousse cake production.

Previous article

Previous article

The 23rd Bakery China will be rescheduled to April 27-30, 2021

Since its establishment in 1997, Bakery China has been committed to serving the whole industry chain in the baking industry and is a professional exhibition for bakery products manufacturing and services.

Nowadays, as China's economic development enters the new normal, the development of various industries in China are moving in the direction of intelligence and automation, which is extremely common especially in labor-intensive industries. As we all know, the goal of automation is to achieve the automatic management of processes, without the need for manpower, thereby reducing the cost of labor and greatly improving production capacity.

Five deficiencies and five trends in the development of my country's baking industry

my country's baking industry has emerged in the 1980s and has flourished since the 21st century. The categories are prosperous and the brands are emerging one after another. Common baked goods such as bread, cakes, biscuits and cookies have become popular choices for Chinese people for breakfast. So, what is the development status of my country's baking industry, and what is the future trend? Industry insiders pointed out that there are still "five deficiencies" in my country's baking industry, and the future development will show "five trends".