All Categories>

19

2024

-

10

Innovative Unloading: Redefining the Mousse Cake Mold Industry

Classification:

【Summary description】Innovative Unloading: Redefining the Mousse Cake Mold Industry Table of Contents 1. Introduction to the Mousse Cake Mold Industry 2. The Challenges of Traditional Unloading Methods 3. The Need for Innovation in Food Processing 4. What is Innovative Unloading? 5. Benefits of Innovative Unloading Technology 6. Case Studies in Innovative Unloading 7. Best Practices for Im

Innovative Unloading: Redefining the Mousse Cake Mold Industry

Table of Contents

- 1. Introduction to the Mousse Cake Mold Industry

- 2. The Challenges of Traditional Unloading Methods

- 3. The Need for Innovation in Food Processing

- 4. What is Innovative Unloading?

- 5. Benefits of Innovative Unloading Technology

- 6. Case Studies in Innovative Unloading

- 7. Best Practices for Implementing Innovative Unloading Techniques

- 8. Future Trends in Mousse Cake Mold Manufacturing

- 9. Conclusion

- 10. FAQs

1. Introduction to the Mousse Cake Mold Industry

The mousse cake mold industry plays a vital role in the culinary sector, especially within the food and beverage processing domain. As a significant contributor to the production of high-quality desserts, mousse cake molds are essential for achieving the desired texture and presentation. In today’s fast-paced market, the demand for efficiency and quality has led to the exploration of innovative unloading methods that promise to redefine the manufacturing landscape.

2. The Challenges of Traditional Unloading Methods

Traditional unloading methods in the mousse cake mold industry often face various challenges. These include:

2.1 Time Inefficiency

Many standard unloading processes are labor-intensive and time-consuming. As manufacturers strive to enhance productivity, these outdated methods hinder operational efficiency.

2.2 Product Damage

Traditional unloading techniques frequently result in product damage. Mousse cakes are delicate, and improper handling can lead to unsightly presentations, which directly affects customer satisfaction.

2.3 Increased Labor Costs

Manual unloading processes require significant human resources, increasing labor costs. As businesses seek to optimize their expenses, these traditional methods become less viable.

3. The Need for Innovation in Food Processing

The food processing industry is experiencing rapid changes driven by consumer demand for quality and efficiency. Factors such as health consciousness, sustainability, and food safety necessitate innovations in equipment and processes. Mousse cake manufacturers must adapt to these changes to remain competitive.

3.1 Meeting Consumer Expectations

Today's consumers expect visually appealing and perfectly-textured desserts. Innovations in unloading can help manufacturers meet these rising expectations.

3.2 Sustainability Considerations

With growing concerns over waste and environmental impact, the food industry is under pressure to adopt sustainable practices. Innovative unloading techniques can minimize waste and improve the overall ecological footprint of manufacturing.

4. What is Innovative Unloading?

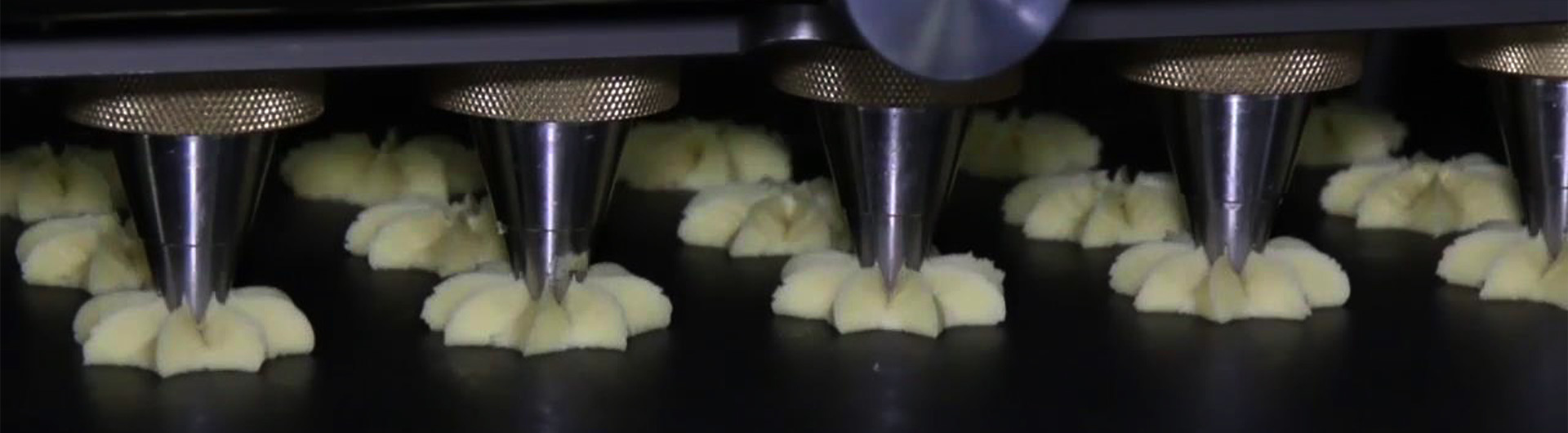

Innovative unloading refers to advanced methods and technologies employed to remove products from molds efficiently and safely. These methods incorporate automation, robotics, and specialized machinery designed to enhance precision and reduce handling times.

4.1 Automation in Unloading

The integration of automation in unloading processes has transformed the industry. Automated systems can quickly and accurately remove mousse cakes from molds, significantly reducing labor and time requirements.

4.2 Robotics and AI Technology

Robotic systems equipped with artificial intelligence can be programmed to handle delicate products gently. This ensures that mousse cakes are perfectly preserved during the unloading process, maintaining their quality and appearance.

5. Benefits of Innovative Unloading Technology

The implementation of innovative unloading technology offers a multitude of benefits:

5.1 Enhanced Efficiency

Automated unloading systems dramatically increase production speed, allowing manufacturers to meet growing demands without compromising quality.

5.2 Improved Product Quality

With precise handling, the risk of product damage is minimized, resulting in consistently high-quality mousse cakes that meet customer expectations.

5.3 Cost Reduction

By reducing labor costs and minimizing waste, innovative unloading contributes to a more cost-effective production process.

5.4 Increased Safety

Automated systems reduce the risk of workplace accidents associated with manual unloading processes, providing a safer working environment for employees.

6. Case Studies in Innovative Unloading

Several companies have successfully adopted innovative unloading techniques, showcasing their effectiveness in the mousse cake mold industry.

6.1 Company A: Streamlining Production

Company A implemented an automated unloading system that increased their production rate by 40%. By utilizing robotic arms for handling, they minimized product damage and improved overall efficiency.

6.2 Company B: Sustainable Practices

Company B focused on implementing eco-friendly unloading methods that reduced waste by 30%. Through strategic investments in technology, they not only improved their bottom line but also enhanced their brand image in sustainability.

7. Best Practices for Implementing Innovative Unloading Techniques

To successfully integrate innovative unloading methods, manufacturers should consider the following best practices:

7.1 Conduct a Needs Assessment

Identifying specific production needs will help determine the most suitable unloading technology for your operations.

7.2 Invest in Employee Training

Proper training is essential for employees to effectively operate new systems and understand the technology's benefits.

7.3 Pilot Testing

A pilot test allows manufacturers to evaluate the effectiveness of new unloading methods before full implementation, ensuring that any issues can be addressed early.

8. Future Trends in Mousse Cake Mold Manufacturing

The mousse cake mold industry is on the brink of significant transformation due to innovative unloading technologies. Key trends to watch include:

8.1 Increased Use of AI and Machine Learning

The application of AI and machine learning will enhance the precision and efficiency of unloading processes, continually adapting to improve production outcomes.

8.2 Sustainable Innovations

The trend towards sustainability will drive the development of eco-friendly unloading solutions that minimize waste and energy consumption.

8.3 Customization and Personalization

As consumer preferences evolve, manufacturers will increasingly seek customizable unloading systems that cater to specific product requirements.

9. Conclusion

The mousse cake mold industry is undergoing a significant transformation driven by innovative unloading methods. By embracing automation and advanced technologies, manufacturers can enhance efficiency, improve product quality, and reduce operational costs. As the industry continues to evolve, staying ahead of these trends will be crucial for businesses aiming to maintain a competitive edge. The future of mousse cake production is promising, with innovative unloading at the forefront of this change.

10. FAQs

Q1: What is the main advantage of innovative unloading in the mousse cake mold industry?

A1: The primary advantage of innovative unloading is increased efficiency, which allows manufacturers to produce higher volumes of mousse cakes while maintaining quality.

Q2: How can automation improve product quality in food processing?

A2: Automation reduces the risk of human error and product damage, ensuring that mousse cakes are handled consistently and safely.

Q3: Are there any sustainability benefits associated with innovative unloading methods?

A3: Yes, innovative unloading methods often lead to reduced waste and lower energy consumption, contributing to more sustainable manufacturing practices.

Q4: What technologies are commonly used in innovative unloading systems?

A4: Technologies such as robotics, AI, and specialized automated machinery are commonly used to enhance unloading processes in the mousse cake mold industry.

Q5: How can manufacturers effectively implement innovative unloading techniques?

A5: Manufacturers should conduct a needs assessment, invest in employee training, and consider pilot testing to ensure successful implementation of innovative unloading techniques.

The 23rd Bakery China will be rescheduled to April 27-30, 2021

Since its establishment in 1997, Bakery China has been committed to serving the whole industry chain in the baking industry and is a professional exhibition for bakery products manufacturing and services.

Nowadays, as China's economic development enters the new normal, the development of various industries in China are moving in the direction of intelligence and automation, which is extremely common especially in labor-intensive industries. As we all know, the goal of automation is to achieve the automatic management of processes, without the need for manpower, thereby reducing the cost of labor and greatly improving production capacity.

Five deficiencies and five trends in the development of my country's baking industry

my country's baking industry has emerged in the 1980s and has flourished since the 21st century. The categories are prosperous and the brands are emerging one after another. Common baked goods such as bread, cakes, biscuits and cookies have become popular choices for Chinese people for breakfast. So, what is the development status of my country's baking industry, and what is the future trend? Industry insiders pointed out that there are still "five deficiencies" in my country's baking industry, and the future development will show "five trends".