All Categories>

04

2024

-

11

Modern Marvels: The Technological Advancements of Round Rainbow Mousse Cake Fillers

Classification:

【Summary description】Modern Marvels: The Technological Advancements of Round Rainbow Mousse Cake Fillers Table of Contents 1. Introduction to Round Rainbow Mousse Cake Fillers 2. Historical Perspective on Cake Fillers 3. Technological Advancements in Food Processing Machinery 4. Design Innovations for Enhanced Aesthetics 5. Efficiency and Productivity Gains 6. Quality Control Mechanisms 7.

Modern Marvels: The Technological Advancements of Round Rainbow Mousse Cake Fillers

Table of Contents

- 1. Introduction to Round Rainbow Mousse Cake Fillers

- 2. Historical Perspective on Cake Fillers

- 3. Technological Advancements in Food Processing Machinery

- 4. Design Innovations for Enhanced Aesthetics

- 5. Efficiency and Productivity Gains

- 6. Quality Control Mechanisms

- 7. Sustainability Initiatives in Cake Production

- 8. Future Trends in Round Rainbow Mousse Cake Fillers

- 9. Frequently Asked Questions

- 10. Conclusion

1. Introduction to Round Rainbow Mousse Cake Fillers

The world of confectionery is ever-evolving, with innovations continually enhancing product offerings and production processes. One of the most visually appealing and delicious desserts in modern culinary arts is the round rainbow mousse cake. The technique of creating these delightful desserts has been significantly enhanced by advances in food processing machinery, specifically in the realm of mousse cake fillers.

Round rainbow mousse cake fillers allow bakers and chefs to create layered mousse cakes with vibrant colors and flavors. This **technological advancement** not only improves efficiency but also enhances creativity in dessert making.

2. Historical Perspective on Cake Fillers

Historically, cake fillers were rudimentary tools designed to inject fillings into cakes. Traditional methods often involved manual labor and lacked precision. As baking evolved, so did the need for better tools. The introduction of basic machinery allowed for quicker preparation, but these machines often fell short in consistency and ease of use.

The transition from manual to automated systems marked a pivotal shift in the industry. As the demand for more intricate and visually stunning cakes grew, so did the innovation surrounding cake fillers. The advent of **modern hydraulic and pneumatic systems** paved the way for the advanced round rainbow mousse cake fillers we see today.

3. Technological Advancements in Food Processing Machinery

Modern round rainbow mousse cake fillers incorporate a variety of **cutting-edge technologies**. Some of the most notable advancements include:

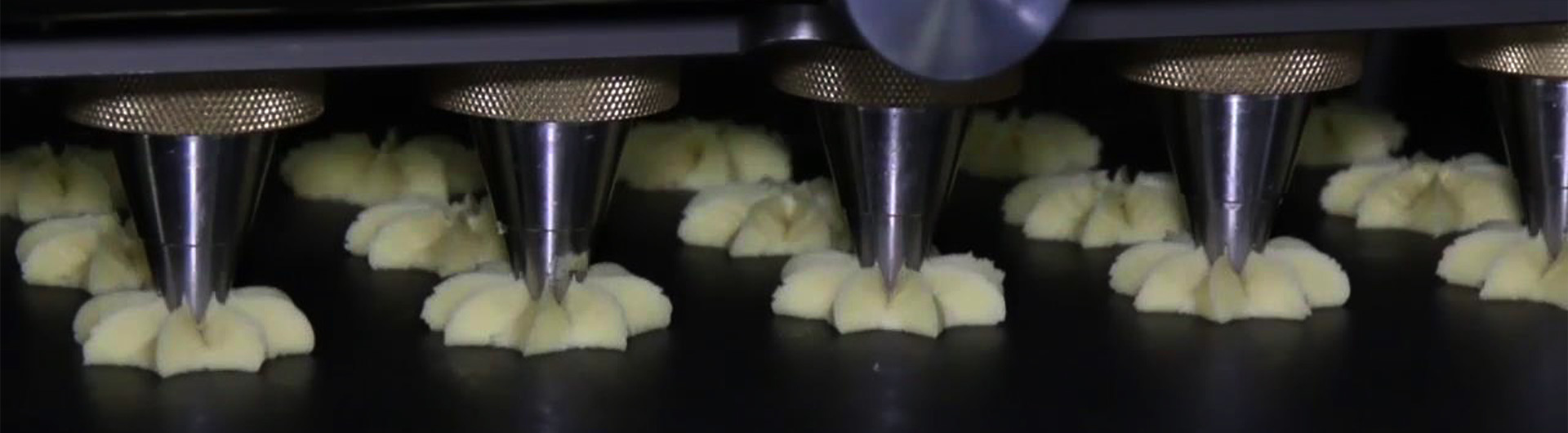

3.1 Precision Dispensing Systems

Current mousse cake fillers utilize precision dispensing systems that ensure uniform distribution of mousse. These systems are equipped with sophisticated sensors and software that adjust the flow rate based on real-time data, resulting in consistent layer thickness and texture.

3.2 Automated Mixing and Temperature Control

The integration of automated mixing processes has transformed how mousse is prepared. With exact temperature control, ingredients can be mixed to the perfect consistency, ensuring optimal flavor and texture. This technology eliminates human error and enhances the overall quality of the mousse.

3.3 Smart Monitoring Systems

Modern fillers often feature smart monitoring systems that track the production process. These systems provide valuable insights into efficiency and product quality, allowing manufacturers to make data-driven decisions that optimize production.

4. Design Innovations for Enhanced Aesthetics

The visual appeal of desserts plays a crucial role in their marketability. Today’s round rainbow mousse cake fillers are designed not just for functionality but also for aesthetics.

4.1 Adjustable Nozzle Designs

One of the most significant innovations is the development of adjustable nozzles that allow bakers to create various designs and patterns. These nozzles enable the production of intricate mousse layers that can be customized for any occasion.

4.2 Color Dispensing Technology

Color dispensing technology has also made a profound impact. This innovation allows for the simultaneous injection of multiple colors, resulting in the vibrant layers characteristic of rainbow mousse cakes. This technology provides endless possibilities for customization, making it a favorite among professional bakers.

5. Efficiency and Productivity Gains

The advancements in round rainbow mousse cake fillers have led to significant gains in efficiency and productivity.

5.1 Reduction in Labor Costs

Automated systems reduce the dependence on manual labor, leading to substantial savings in labor costs. With machines handling the bulk of the filling process, bakeries can allocate their workforce to other areas, enhancing overall productivity.

5.2 Time Savings in Production

With the speed and precision of modern fillers, the production time for round rainbow mousse cakes has drastically decreased. This increase in speed allows bakeries to meet rising demand without compromising on quality.

6. Quality Control Mechanisms

Maintaining quality is paramount in food processing. Modern round rainbow mousse cake fillers are equipped with advanced quality control mechanisms that ensure every batch meets stringent standards.

6.1 Real-time Quality Monitoring

Using sophisticated sensors and software, manufacturers can perform real-time quality checks during the production process. Any deviations from set parameters can be quickly addressed, ensuring consistent quality across batches.

6.2 Automated Cleaning Systems

To meet hygiene standards, modern fillers feature automated cleaning systems that ensure thorough sanitation between production runs. This innovation minimizes downtime and ensures that equipment is always ready for use.

7. Sustainability Initiatives in Cake Production

In today’s world, sustainability is a growing concern in all industries, including food production. The development of environmentally friendly round rainbow mousse cake fillers is a testament to the industry’s commitment to sustainability.

7.1 Energy-efficient Machinery

Many modern fillers are designed to consume less energy during operation. This energy efficiency not only reduces costs for manufacturers but also minimizes their carbon footprint.

7.2 Sustainable Materials

The use of sustainable materials in the construction of cake fillers is becoming more prevalent. Manufacturers are increasingly sourcing eco-friendly materials, contributing to a more sustainable production process.

8. Future Trends in Round Rainbow Mousse Cake Fillers

As technology continues to evolve, the future of round rainbow mousse cake fillers looks promising. Here are some trends to watch for:

8.1 Integration of Artificial Intelligence

The incorporation of artificial intelligence (AI) could revolutionize the food processing industry. AI could analyze data trends and optimize production processes, further enhancing efficiency and product quality.

8.2 Customizable User Interfaces

Future fillers may feature customizable user interfaces, allowing operators to tailor settings according to their specific needs. This flexibility could lead to more creative possibilities in dessert design.

9. Frequently Asked Questions

9.1 What are round rainbow mousse cake fillers?

Round rainbow mousse cake fillers are specialized machines designed to inject mousse into cake layers, helping bakers create visually appealing, multi-colored desserts.

9.2 How do modern fillers improve efficiency?

Modern fillers enhance efficiency through automation, precise dispensing, and real-time monitoring, significantly reducing production time and labor costs.

9.3 Are there sustainability initiatives in mousse cake production?

Yes, many manufacturers are adopting energy-efficient machinery and utilizing sustainable materials to minimize environmental impact.

9.4 What innovations are driving design improvements?

Adjustable nozzles and color dispensing technology are key innovations that allow for intricate designs and vibrant colors in mousse cakes.

9.5 How can I choose the right round rainbow mousse cake filler for my bakery?

Consider factors like production capacity, ease of use, maintenance requirements, and the specific features that align with your business needs.

10. Conclusion

In conclusion, round rainbow mousse cake fillers represent the intersection of culinary artistry and technological innovation. The advancements in food processing machinery not only streamline production but also open new avenues for creativity in dessert making. As the industry continues to evolve, we can expect even more exciting developments that will further enhance the way we approach cake design and production. By embracing these modern marvels, bakers can create stunning desserts that captivate both the eye and the palate, ensuring a bright future for the world of confectionery.

The 23rd Bakery China will be rescheduled to April 27-30, 2021

Since its establishment in 1997, Bakery China has been committed to serving the whole industry chain in the baking industry and is a professional exhibition for bakery products manufacturing and services.

Nowadays, as China's economic development enters the new normal, the development of various industries in China are moving in the direction of intelligence and automation, which is extremely common especially in labor-intensive industries. As we all know, the goal of automation is to achieve the automatic management of processes, without the need for manpower, thereby reducing the cost of labor and greatly improving production capacity.

Five deficiencies and five trends in the development of my country's baking industry

my country's baking industry has emerged in the 1980s and has flourished since the 21st century. The categories are prosperous and the brands are emerging one after another. Common baked goods such as bread, cakes, biscuits and cookies have become popular choices for Chinese people for breakfast. So, what is the development status of my country's baking industry, and what is the future trend? Industry insiders pointed out that there are still "five deficiencies" in my country's baking industry, and the future development will show "five trends".