All Categories>

10

2024

-

11

The Future of Food Industry: Innovative Trends in Mousse Cake Circular Production Lines

Classification:

【Summary description】The Future of Food Industry: Innovative Trends in Mousse Cake Circular Production Lines Introduction: Evolution of Mousse Cake Production In recent years, the food industry has witnessed significant transformations, propelled by advancements in technology and changing consumer preferences. Mousse cakes, known for their delicate texture and rich flavors, are becoming increasingly popular in bakerie

The Future of Food Industry: Innovative Trends in Mousse Cake Circular Production Lines

Introduction: Evolution of Mousse Cake Production

In recent years, the food industry has witnessed significant transformations, propelled by advancements in technology and changing consumer preferences. Mousse cakes, known for their delicate texture and rich flavors, are becoming increasingly popular in bakeries and restaurants worldwide. To meet rising demand while maintaining quality and efficiency, manufacturers are turning to **circular production lines**. This article explores the latest trends in mousse cake circular production lines, highlighting their benefits, technological innovations, and future implications for the food industry.

Table of Contents

1. Understanding Circular Production Lines in Food Processing

2. Technological Innovations Driving Mousse Cake Production

3. Sustainability Trends in the Food Industry

4. Benefits of Circular Production Lines for Mousse Cake Manufacturing

5. Case Studies: Successful Implementation of Circular Production Lines

6. Future Trends in Mousse Cake Production Lines

7. Challenges and Solutions in Adopting Circular Production Lines

8. Conclusion: The Path Forward for the Food Industry

9. FAQs about Mousse Cake Circular Production Lines

Understanding Circular Production Lines in Food Processing

Circular production lines represent a significant shift from traditional linear food production methods. These systems are designed to optimize the flow of materials and minimize waste, effectively creating a closed-loop system. In mousse cake manufacturing, circular production lines enhance the efficiency of ingredient mixing, baking, cooling, and packaging processes.

By integrating advanced machinery and automation, these production lines streamline operations, reduce labor costs, and improve overall product quality. The shift to a circular approach not only meets the growing demand for mousse cakes but also aligns with sustainability goals by minimizing resource consumption and waste generation.

Technological Innovations Driving Mousse Cake Production

The landscape of mousse cake production is rapidly evolving, largely due to technological innovations. Key advancements include:

1. Automation and Robotics

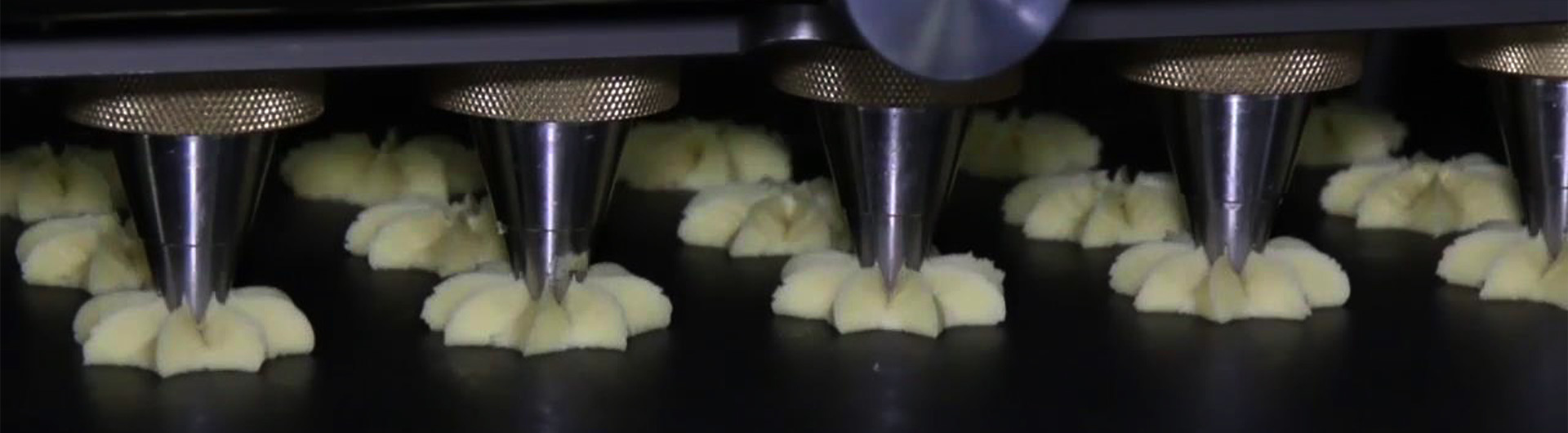

Robotic systems are increasingly being integrated into mousse cake production lines, enhancing precision and speed. Robots can perform tasks such as ingredient dispensing, mixing, and even decorating cakes with remarkable accuracy. This automation reduces human error and improves consistency in product quality.

2. IoT and Smart Sensors

The Internet of Things (IoT) is transforming food manufacturing by enabling real-time monitoring and data analysis. Smart sensors placed throughout the production line can track temperature, humidity, and other critical parameters, ensuring optimal conditions for mousse cake production. This data-driven approach enhances quality control and allows for quick adjustments to the production process.

3. Advanced Mixing Technology

New mixing technologies, such as high-shear mixers and vacuum mixing systems, are improving the aeration of mousse cake batters. These innovations create the light, airy texture that mousse cakes are known for while reducing mixing time. The result is a product that meets consumer expectations for quality without sacrificing efficiency.

Sustainability Trends in the Food Industry

As consumers become increasingly conscious of environmental issues, sustainability has become a driving force in the food industry. Circular production lines contribute to sustainability in several ways:

1. Waste Reduction

Circular production systems are designed to minimize waste by reusing by-products and optimizing resource use. In mousse cake production, any excess batter can be reclaimed and repurposed, thus reducing overall waste.

2. Energy Efficiency

Modern production lines are engineered for energy efficiency. Manufacturers are adopting energy-efficient machinery and practices that lower energy consumption during production, contributing to a smaller carbon footprint.

3. Sustainable Sourcing

More producers are prioritizing the use of sustainably sourced ingredients. From organic cocoa to free-range eggs, the commitment to ethical sourcing aligns production practices with consumer expectations for transparency and sustainability.

Benefits of Circular Production Lines for Mousse Cake Manufacturing

Implementing circular production lines in mousse cake manufacturing presents numerous advantages:

1. Increased Efficiency

These systems are designed to streamline processes, significantly reducing production time and labor costs. With automated workflows and optimized layouts, manufacturers can increase output without compromising quality.

2. Enhanced Product Quality

The integration of advanced technology ensures consistent product quality. Automated mixing and precise temperature controls lead to superior texture and flavor in mousse cakes, meeting consumer expectations.

3. Flexibility in Production

Circular production lines offer flexibility to adapt to changing market demands. Manufacturers can easily adjust production volumes and flavors without significant downtime or reconfiguration of the production line.

Case Studies: Successful Implementation of Circular Production Lines

Several companies have successfully adopted circular production lines in their mousse cake manufacturing processes, yielding significant benefits:

1. Company A: Revolutionizing Production

Company A integrated a circular production line that automated their mousse cake assembly. This change reduced production time by 30% and improved overall product quality. The company also implemented real-time monitoring systems, allowing for immediate adjustments based on production data.

2. Company B: Commitment to Sustainability

Company B introduced a circular production model focused on sustainability. By reclaiming excess batter and utilizing energy-efficient machinery, the company achieved a 25% reduction in waste and energy consumption. This commitment to sustainability resonated with environmentally conscious consumers, boosting sales.

Future Trends in Mousse Cake Production Lines

Looking ahead, several trends are likely to shape the future of mousse cake production lines:

1. Increased Customization

As consumer preferences become more diverse, the demand for customized mousse cakes is expected to rise. Circular production lines will need to adapt, offering flexibility in flavor combinations and designs.

2. Adoption of AI and Machine Learning

Artificial intelligence (AI) and machine learning will play a significant role in optimizing production processes. These technologies will analyze production data to predict maintenance needs, enhance quality control, and improve overall efficiency.

3. Greater Emphasis on Health and Wellness

The growing trend towards health and wellness will lead to increased demand for healthier mousse cake options. Manufacturers may explore alternative ingredients, such as plant-based alternatives, to meet consumer preferences.

Challenges and Solutions in Adopting Circular Production Lines

While circular production lines offer many benefits, challenges remain in their adoption.

1. High Initial Investment

The upfront costs associated with implementing advanced machinery and technology can be a barrier for some manufacturers. However, the long-term savings in labor and waste reduction often justify the initial expenditure.

2. Training and Skill Development

Employees may require training to adapt to new technologies and workflows. Investing in staff development is crucial for maximizing the benefits of circular production lines.

3. Integrating Existing Systems

Integrating circular production lines with existing systems can be complex. Manufacturers should carefully plan the implementation process to ensure a smooth transition.

Conclusion: The Path Forward for the Food Industry

The mousse cake circular production line represents a significant advancement in the food manufacturing sector. As technology continues to evolve, we can expect to see even greater efficiency, sustainability, and product quality in the future. Embracing these innovations will not only help manufacturers meet consumer demands but also contribute to a more sustainable food industry.

FAQs about Mousse Cake Circular Production Lines

1. What is a circular production line?

A circular production line is a manufacturing system designed to optimize the flow of materials and minimize waste by creating a closed-loop system.

2. How do circular production lines improve efficiency?

These systems streamline processes, reduce production time, and lower labor costs through automation and optimized workflows.

3. What technologies are used in mousse cake production lines?

Technologies such as automation, IoT, smart sensors, and advanced mixing systems are commonly used to enhance production efficiency and quality.

4. How does sustainability play a role in mousse cake production?

Sustainability is achieved through waste reduction, energy efficiency, and the use of sustainably sourced ingredients, aligning production practices with consumer preferences.

5. What are the future trends in mousse cake production?

Future trends include increased customization, the adoption of AI and machine learning, and a greater emphasis on health and wellness in product offerings.

Previous article

The 23rd Bakery China will be rescheduled to April 27-30, 2021

Since its establishment in 1997, Bakery China has been committed to serving the whole industry chain in the baking industry and is a professional exhibition for bakery products manufacturing and services.

Nowadays, as China's economic development enters the new normal, the development of various industries in China are moving in the direction of intelligence and automation, which is extremely common especially in labor-intensive industries. As we all know, the goal of automation is to achieve the automatic management of processes, without the need for manpower, thereby reducing the cost of labor and greatly improving production capacity.

Five deficiencies and five trends in the development of my country's baking industry

my country's baking industry has emerged in the 1980s and has flourished since the 21st century. The categories are prosperous and the brands are emerging one after another. Common baked goods such as bread, cakes, biscuits and cookies have become popular choices for Chinese people for breakfast. So, what is the development status of my country's baking industry, and what is the future trend? Industry insiders pointed out that there are still "five deficiencies" in my country's baking industry, and the future development will show "five trends".