All Categories>

21

2024

-

12

Unleashing the Potential: The Role of Bread Cutting and Filling Machines in Modern Bakeries

Classification:

【Summary description】Unleashing the Potential: The Role of Bread Cutting and Filling Machines in Modern Bakeries Table of Contents Introduction to Bread Cutting and Filling Machines The Importance of Automated Bakery Machinery Types of Bread Cutting and Filling Machines Bread Cutting Machines Filling Machines Benefits of Using Bread Cutting and Filling Machine

Unleashing the Potential: The Role of Bread Cutting and Filling Machines in Modern Bakeries

Table of Contents

- Introduction to Bread Cutting and Filling Machines

- The Importance of Automated Bakery Machinery

- Types of Bread Cutting and Filling Machines

- Benefits of Using Bread Cutting and Filling Machines

- Innovations in Bread Cutting and Filling Technology

- Challenges in Implementing Bakery Machinery

- The Future of Bakery Machinery

- Frequently Asked Questions

- Conclusion

Introduction to Bread Cutting and Filling Machines

In the fast-paced world of modern bakeries, efficiency and precision are paramount. Bread cutting and filling machines have emerged as invaluable assets, enabling bakers to streamline their operations while delivering high-quality products that meet customer expectations. By automating key processes, these machines not only save time but also enhance the consistency and visual appeal of baked goods.

The Importance of Automated Bakery Machinery

As consumer demand for artisanal and specialty breads continues to rise, bakeries are pushed to innovate and adapt. **Automated bakery machinery**, including bread cutting and filling machines, allows bakers to scale production without sacrificing quality. These machines can handle large volumes, maintain uniformity in products, and alleviate the labor-intensive processes that are traditionally associated with baking.

The Shift Towards Automation

The shift towards automation in bakeries is driven by several factors, including the increasing cost of labor, the need for efficiency, and the desire to produce consistent quality. With bread cutting and filling machines, bakeries can optimize their workflows and significantly reduce the time taken to prepare products for sale.

Types of Bread Cutting and Filling Machines

Understanding the various types of bread cutting and filling machines is essential for bakery owners looking to enhance their operations. Each machine type serves a specific purpose and can be tailored to meet the unique needs of a bakery.

Bread Cutting Machines

Bread cutting machines are designed to slice loaves of bread uniformly and efficiently. They come in various configurations, including:

- **Manual Bread Slicers**: Simple, user-operated machines ideal for small bakeries with lower production needs.

- **Automatic Bread Slicers**: Suitable for larger operations, these machines can slice multiple loaves simultaneously with adjustable thickness settings.

- **Continuous Bread Slicers**: High-capacity machines designed for mass production, capable of slicing thousands of loaves per hour.

Each type of bread cutting machine offers unique advantages, ensuring that bakeries can find the right fit for their production scale and product offerings.

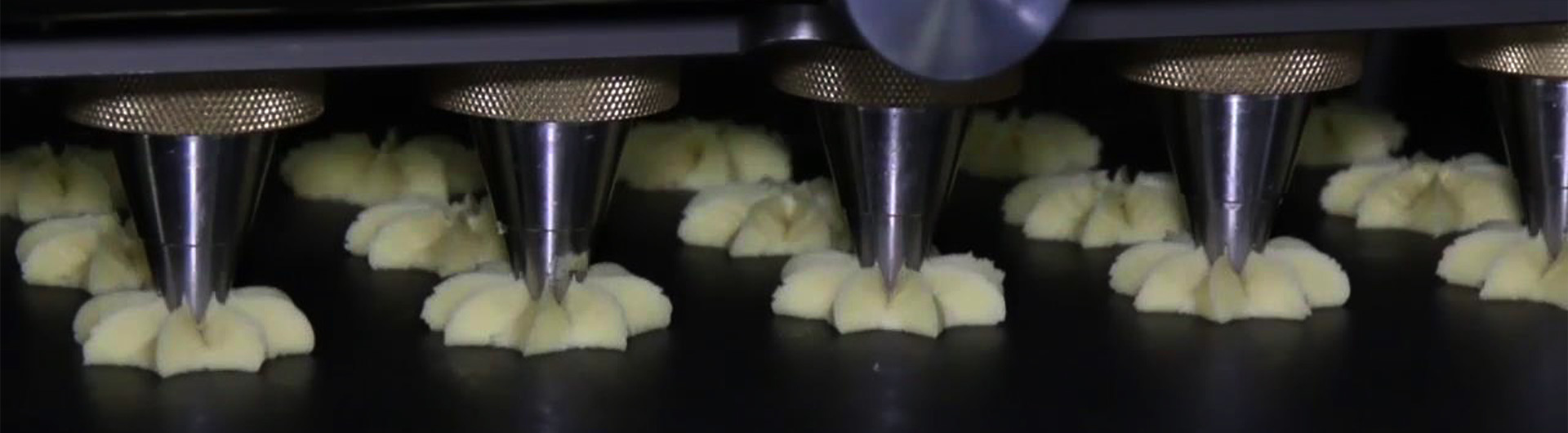

Filling Machines

Filling machines are crucial for bakeries specializing in filled breads, pastries, and other products. They enable the precise injection of fillings such as creams, jams, or other ingredients. Key types of filling machines include:

- **Piston Fillers**: Ideal for thick fillings, these machines use a piston to dispense precise amounts of filling into each product.

- **Volumetric Fillers**: Designed for liquid or semi-liquid fillings, volumetric fillers ensure consistency in volume across products.

- **Auger Fillers**: Suitable for granular or powdery fillings, these machines utilize an auger mechanism to control the flow of filling.

Benefits of Using Bread Cutting and Filling Machines

Incorporating bread cutting and filling machines into bakery operations provides several significant benefits:

1. Increased Efficiency

Automated machines can operate at a much faster pace than manual labor, allowing bakeries to produce more products in less time. This increased efficiency can lead to higher profits and the ability to meet rising consumer demands.

2. Consistency in Quality

One of the primary advantages of using specialized machinery is the ability to maintain consistent quality. Bread cutting machines ensure uniform slice sizes, while filling machines provide precise amounts of filling, resulting in products that meet customer expectations every time.

3. Labor Cost Savings

With automation, bakeries can reduce their reliance on manual labor, which can be a significant cost factor. By investing in machines, bakeries can redirect their human resources toward more creative or quality-control tasks, further enhancing product offerings.

4. Enhanced Product Variety

The integration of cutting and filling machines allows bakeries to diversify their product lines. Bakers can experiment with different kinds of fillings and bread types, appealing to a broader customer base and adapting to market trends.

Innovations in Bread Cutting and Filling Technology

The bakery machinery industry is continually evolving, with innovative technologies enhancing the functionality and efficiency of bread cutting and filling machines. Some recent advancements include:

1. Smart Automation

Modern machines come equipped with smart automation features that enable real-time monitoring and adjustments. This technology allows bakers to track production metrics, minimize waste, and optimize workflows.

2. Hygiene and Safety Enhancements

With an increased focus on food safety, many machines are now designed with easy-to-clean surfaces and materials that meet health regulations. Innovations in hygiene technology ensure that bakeries maintain the highest standards of cleanliness.

3. Energy Efficiency

Newer models of bread cutting and filling machines are designed to consume less energy, reducing operational costs and environmental impact. This energy-efficient technology is crucial as bakeries look for ways to minimize their carbon footprint.

4. Customization Options

Many manufacturers now offer customizable machines that can be tailored to specific bakery needs. This flexibility allows bakeries to choose features that best align with their production goals and product types.

Challenges in Implementing Bakery Machinery

While the advantages are numerous, bakeries may face challenges when implementing new machinery:

1. Initial Investment Costs

Purchasing high-quality bread cutting and filling machines can represent a significant upfront investment. Smaller bakeries may struggle to allocate funds for such purchases, despite the long-term savings.

2. Training Requirements

With advanced machinery comes the need for proper training. Staff must be educated on machine operation, maintenance, and troubleshooting to maximize the benefits of automation.

3. Maintenance and Repairs

Regular maintenance is crucial to ensure machines operate efficiently. Bakeries must also be prepared for the potential costs of repairs, as downtime can impact production schedules.

The Future of Bakery Machinery

The future of bread cutting and filling machines looks promising as technology continues to advance. With ongoing innovations in automation, customization, and efficiency, bakeries can expect even greater capabilities that will further enhance their operations. As consumer preferences evolve, these machines will play a crucial role in allowing bakeries to adapt and thrive in an increasingly competitive market.

Frequently Asked Questions

1. What are the key features to look for in bread cutting machines?

When selecting a bread cutting machine, consider features like adjustable slice thickness, speed, ease of cleaning, and safety mechanisms.

2. How do filling machines ensure consistency in products?

Filling machines utilize precise mechanisms, such as pistons or augers, to control the volume of filling used, ensuring product uniformity.

3. Can these machines be used for different types of bread?

Yes, many bread cutting and filling machines are versatile and can accommodate various bread types, including artisanal loaves, baguettes, and filled pastries.

4. What is the average lifespan of bakery machinery?

The lifespan of bakery machinery varies but generally ranges from 10 to 20 years, depending on usage, maintenance, and build quality.

5. Are there any regulatory standards for bakery machinery?

Yes, bakery machinery must meet food safety regulations, which vary by region. Compliance with hygiene and safety standards is crucial for bakery operations.

Conclusion

In conclusion, bread cutting and filling machines are vital components of modern bakeries, driving efficiency, consistency, and quality in production. As the industry continues to evolve, these machines will enhance bakeries' ability to meet demand, diversify product offerings, and maintain high standards of quality. Investing in the right bakery machinery is not just a step towards modernization; it's a commitment to excellence that can propel bakeries to new heights in an increasingly competitive market.

Previous article

Previous article

The 23rd Bakery China will be rescheduled to April 27-30, 2021

Since its establishment in 1997, Bakery China has been committed to serving the whole industry chain in the baking industry and is a professional exhibition for bakery products manufacturing and services.

Nowadays, as China's economic development enters the new normal, the development of various industries in China are moving in the direction of intelligence and automation, which is extremely common especially in labor-intensive industries. As we all know, the goal of automation is to achieve the automatic management of processes, without the need for manpower, thereby reducing the cost of labor and greatly improving production capacity.

Five deficiencies and five trends in the development of my country's baking industry

my country's baking industry has emerged in the 1980s and has flourished since the 21st century. The categories are prosperous and the brands are emerging one after another. Common baked goods such as bread, cakes, biscuits and cookies have become popular choices for Chinese people for breakfast. So, what is the development status of my country's baking industry, and what is the future trend? Industry insiders pointed out that there are still "five deficiencies" in my country's baking industry, and the future development will show "five trends".