All Categories>

31

2024

-

10

Enhancing Quality Control in Bread Production with Cutting and Filling Machines

Classification:

【Summary description】Enhancing Quality Control in Bread Production with Cutting and Filling Machines Table of Contents 1. Introduction to Quality Control in Bread Production 2. Importance of Quality Control in the Baking Industry 3. Understanding Cutting and Filling Machines 4. The Technology Behind Cutting and Filling Machines 5. Benefits of Using Cutting and Filling Machines in Bread Production

Enhancing Quality Control in Bread Production with Cutting and Filling Machines

Table of Contents

- 1. Introduction to Quality Control in Bread Production

- 2. Importance of Quality Control in the Baking Industry

- 3. Understanding Cutting and Filling Machines

- 4. The Technology Behind Cutting and Filling Machines

- 5. Benefits of Using Cutting and Filling Machines in Bread Production

- 6. Implementing Cutting and Filling Machines in Your Bakery

- 7. Common Challenges in Bread Production and Their Solutions

- 8. The Future of Bakery Technology and Quality Control

- 9. Frequently Asked Questions

- 10. Conclusion

1. Introduction to Quality Control in Bread Production

In the competitive world of bread production, maintaining high standards of quality is essential for success. **Quality control** encompasses a variety of processes and measures aimed at ensuring that every loaf of bread meets specific standards of taste, texture, and appearance. With the advent of **cutting and filling machines**, bakeries can enhance their quality control measures significantly, ensuring that their products not only meet but exceed consumer expectations.

2. Importance of Quality Control in the Baking Industry

Quality control is crucial for several reasons:

- **Customer Satisfaction**: Consistent quality leads to satisfied customers, who are more likely to return for repeat purchases.

- **Brand Reputation**: High-quality products enhance a bakery's reputation and can lead to increased market share.

- **Cost Reduction**: Effective quality control reduces waste and rework, saving costs in the long run.

- **Compliance**: Meeting health and safety standards is vital for any food production facility.

By implementing robust quality control measures, bakeries can secure their position in the market and ensure the longevity of their brand.

3. Understanding Cutting and Filling Machines

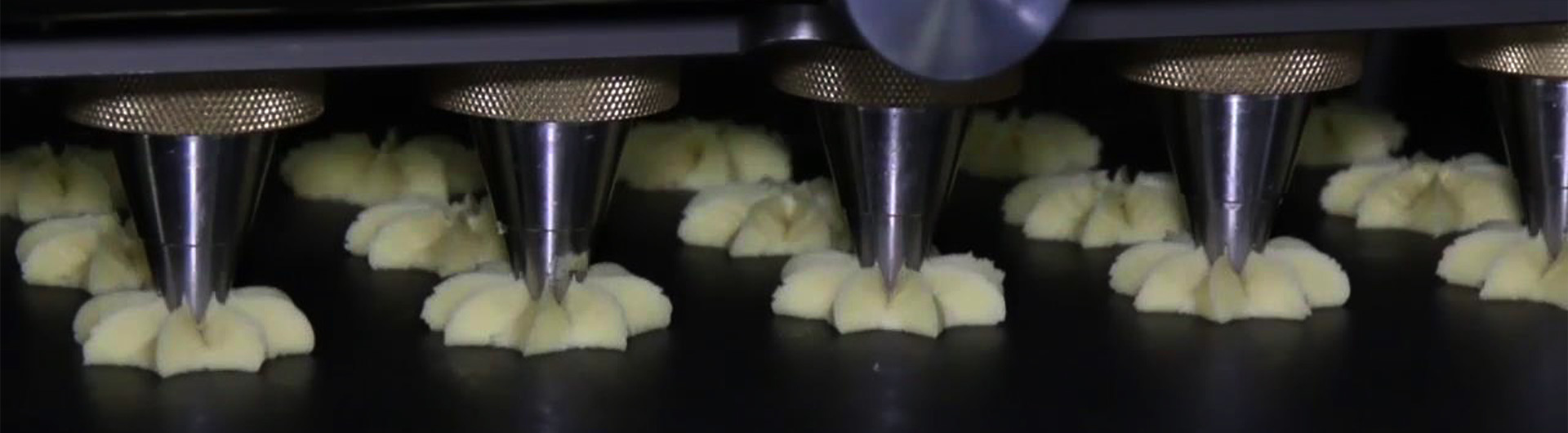

Cutting and filling machines are specialized equipment used in the bread production process. These machines automate the cutting of bread into precise slices and facilitate the filling of bread products with various ingredients, such as creams, jams, or fillings.

The automation of these processes not only enhances efficiency but also ensures consistency in size and filling quantity, which are critical for maintaining quality.

3.1 Types of Cutting Machines

- **Slicing Machines**: Designed for uniform slicing of loaves, ensuring that each slice is of equal thickness.

- **Dicing Machines**: These can cut bread into cubes for specific culinary uses, such as bread crumbs or stuffing.

3.2 Types of Filling Machines

- **Piston Fillers**: Suitable for thick fillings, they provide accurate portion control.

- **Pump Fillers**: Ideal for liquid fillings, offering versatility in production.

4. The Technology Behind Cutting and Filling Machines

Modern cutting and filling machines utilize advanced technologies that contribute to their efficiency and reliability.

4.1 Automation and Robotics

Automation technology in cutting and filling machines allows for high-speed production and minimal human intervention. Robotic arms can handle delicate bread products, ensuring precision cutting and filling without damaging the product.

4.2 Sensor Technology

Sensors play a crucial role in monitoring the operations of cutting and filling machines. They help detect any inconsistencies in the cutting process and ensure that the filling is accurately dispensed, thereby maintaining product quality.

5. Benefits of Using Cutting and Filling Machines in Bread Production

Integrating cutting and filling machines into your bread production process offers numerous benefits:

5.1 Enhanced Consistency

With automated machines, bakeries can achieve uniformity in size, shape, and filling across all products. This consistency is vital for brand recognition and customer loyalty.

5.2 Increased Efficiency

Automated processes reduce production time and labor costs, allowing bakeries to focus on other critical areas while the machines handle repetitive tasks.

5.3 Improved Safety

Minimizing human contact with bread products reduces the risk of contamination, ensuring a safer final product for consumers.

5.4 Versatility in Production

Cutting and filling machines can be easily adjusted to accommodate different types of bread and filling, making them a versatile addition to any bakery.

6. Implementing Cutting and Filling Machines in Your Bakery

To successfully implement cutting and filling machines in your production line, consider the following steps:

6.1 Assess Your Needs

Evaluate your production volume and product variety to determine the right type of machines for your bakery.

6.2 Select the Right Equipment

Choose machines that align with your production goals and can easily integrate into your existing workflow.

6.3 Train Your Staff

Ensure that your team is well-trained in operating the new machines to maximize their potential and maintain safety standards.

7. Common Challenges in Bread Production and Their Solutions

While cutting and filling machines offer numerous advantages, bakeries may face challenges during their integration.

7.1 Equipment Costs

Investing in high-quality machines can be costly. However, the long-term savings in labor and waste reduction can offset the initial investment.

7.2 Maintenance Requirements

Regular maintenance is essential to ensure optimal performance. Establish a maintenance schedule to prevent breakdowns and extend the life of the machines.

7.3 Learning Curve

Staff may initially struggle with new technology. Comprehensive training programs can help ease the transition.

8. The Future of Bakery Technology and Quality Control

The future of bakery technology is expected to focus on further automation, artificial intelligence, and enhanced user interfaces. These advancements will not only streamline processes but also enable bakeries to adapt quickly to changing consumer preferences and market demands.

9. Frequently Asked Questions

1. What types of bread can be produced using cutting and filling machines?

Cutting and filling machines can accommodate various bread types, including loaves, rolls, and filled pastries, allowing for diverse product offerings.

2. How do cutting and filling machines improve food safety?

By minimizing human contact and ensuring precise filling, these machines significantly reduce the risk of contamination, enhancing food safety.

3. Are cutting and filling machines easy to maintain?

Yes, most machines come with maintenance guidelines. Regular checks and cleaning can help maintain their efficiency and longevity.

4. What is the average cost of cutting and filling machines?

Costs can vary widely based on machine specifications and capabilities, typically ranging from a few thousand to tens of thousands of dollars.

5. Can I customize the settings on cutting and filling machines?

Most modern machines allow for customization of settings, enabling bakeries to adjust for different bread types and filling requirements.

10. Conclusion

Enhancing quality control in bread production is crucial for any bakery aiming to succeed in today’s competitive market. By integrating cutting and filling machines into your production line, you can ensure consistency, improve efficiency, and elevate product quality. As technology continues to advance, embracing these innovations will position your bakery for future growth and success. By prioritizing quality control, you not only satisfy your customers but also secure your business's reputation in the long run.

The 23rd Bakery China will be rescheduled to April 27-30, 2021

Since its establishment in 1997, Bakery China has been committed to serving the whole industry chain in the baking industry and is a professional exhibition for bakery products manufacturing and services.

Nowadays, as China's economic development enters the new normal, the development of various industries in China are moving in the direction of intelligence and automation, which is extremely common especially in labor-intensive industries. As we all know, the goal of automation is to achieve the automatic management of processes, without the need for manpower, thereby reducing the cost of labor and greatly improving production capacity.

Five deficiencies and five trends in the development of my country's baking industry

my country's baking industry has emerged in the 1980s and has flourished since the 21st century. The categories are prosperous and the brands are emerging one after another. Common baked goods such as bread, cakes, biscuits and cookies have become popular choices for Chinese people for breakfast. So, what is the development status of my country's baking industry, and what is the future trend? Industry insiders pointed out that there are still "five deficiencies" in my country's baking industry, and the future development will show "five trends".