All Categories>

01

2024

-

11

Maximizing Efficiency with Special Filling Machines in Production Lines

Classification:

【Summary description】In the realm of manufacturing and processing machinery, particularly within the packaging industry, the term “Production Line Special Filling Machine” denotes a significant technological innovation that caters to a variety of filling requirements. These machines are designed to fill products into containers of varying shapes and sizes with extreme accuracy and speed, making them essential assets o

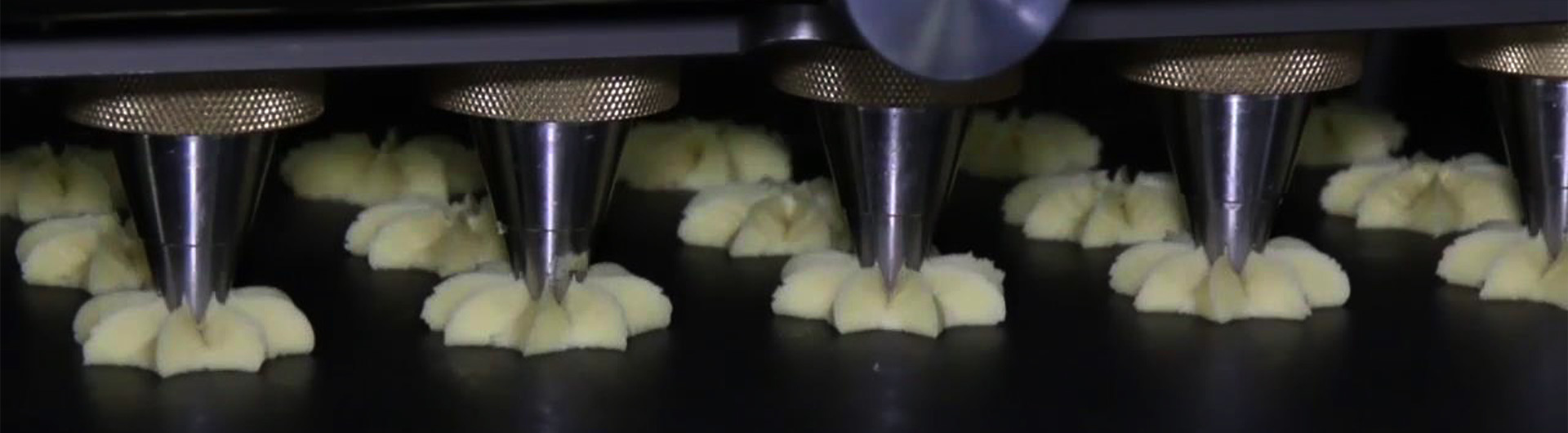

One of the primary benefits of a special filling machine is its customization capability. Depending on the specific needs of the product being filled—be it liquid, powder, granules, or other materials—these machines can be tailored to meet unique filling specifications. This flexibility not only enhances operational efficiency but also allows manufacturers to diversify their product offerings without investing in multiple different machines.

Moreover, the integration of advanced technologies such as PLC (Programmable Logic Controller) systems enables real-time monitoring and control of the filling process. This results in reduced human error, consistent fill volumes, and minimized waste. With features like automatic adjustment for different container sizes and types, production lines can switch from one product to another with minimal downtime, maintaining a smooth workflow.

Special filling machines also prioritize hygiene and safety, which are critical components in industries like food and pharmaceuticals. Many machines are designed with easy-to-clean components and materials that comply with health regulations. Implementing such machines not only ensures product integrity but also protects consumers and enhances brand reputation.

In terms of efficiency, production line special filling machines can significantly increase output rates when compared to manual filling processes. High-speed operations coupled with precise measurement capabilities allow for higher productivity levels, which ultimately lead to better profitability. Additionally, with the ability to implement automation, manufacturers can streamline their workforce, allowing employees to focus on more complex tasks that require human oversight.

Furthermore, these machines often come equipped with advanced features such as automatic capping, labeling, and even packaging, creating an integrated solution that can handle multiple aspects of the production process. By reducing the need for separate machines, companies can save on floor space and maintenance costs, simplifying their operations.

In summary, the implementation of a production line special filling machine can revolutionize the way businesses approach their manufacturing processes. By providing versatility, efficiency, and compliance with industry standards, these machines not only enhance productivity but also contribute to a more sustainable and profitable manufacturing operation. Investing in such technology can be a game-changer for companies looking to stay competitive in the ever-evolving packaging landscape.

The 23rd Bakery China will be rescheduled to April 27-30, 2021

Since its establishment in 1997, Bakery China has been committed to serving the whole industry chain in the baking industry and is a professional exhibition for bakery products manufacturing and services.

Nowadays, as China's economic development enters the new normal, the development of various industries in China are moving in the direction of intelligence and automation, which is extremely common especially in labor-intensive industries. As we all know, the goal of automation is to achieve the automatic management of processes, without the need for manpower, thereby reducing the cost of labor and greatly improving production capacity.

Five deficiencies and five trends in the development of my country's baking industry

my country's baking industry has emerged in the 1980s and has flourished since the 21st century. The categories are prosperous and the brands are emerging one after another. Common baked goods such as bread, cakes, biscuits and cookies have become popular choices for Chinese people for breakfast. So, what is the development status of my country's baking industry, and what is the future trend? Industry insiders pointed out that there are still "five deficiencies" in my country's baking industry, and the future development will show "five trends".