All Categories>

02

2024

-

11

Beyond Traditional Methods: Innovations in Filling Machine Technology

Classification:

【Summary description】Beyond Traditional Methods: Innovations in Filling Machine Technology Table of Contents 1. Introduction to Filling Machine Technology 2. Historical Context of Filling Machines 3. The Shift to Automated Filling Solutions 4. Key Innovations in Filling Machinery 4.1 Advanced Sensor Technology 4.2 AI and Machine Learning in Filling Processes 4.3 Eco-friendly Filling Solutions 4.4 Flexible and Modular

Beyond Traditional Methods: Innovations in Filling Machine Technology

Table of Contents

1. Introduction to Filling Machine Technology

2. Historical Context of Filling Machines

3. The Shift to Automated Filling Solutions

4. Key Innovations in Filling Machinery

4.1 Advanced Sensor Technology

4.2 AI and Machine Learning in Filling Processes

4.3 Eco-friendly Filling Solutions

4.4 Flexible and Modular Designs

5. Impact of Innovations on Efficiency and Productivity

6. Regulatory Compliance and Industry Standards

7. Case Studies: Successful Implementations of New Technologies

8. Future Trends in Filling Machine Technology

9. Frequently Asked Questions (FAQs)

10. Conclusion

1. Introduction to Filling Machine Technology

In the fast-paced world of manufacturing and packaging, filling machines play a crucial role in ensuring that products are delivered efficiently and accurately to consumers. As consumer demands evolve, so too does the technology that supports these processes. In this article, we delve into the **innovations in filling machine technology** that are redefining the landscape of the industry.

2. Historical Context of Filling Machines

Filling machines have been around for decades, evolving from manual systems to more complex automated solutions. Initially, these machines were limited in their capabilities, often requiring skilled operators to manage the filling process. As technology progressed, the need for efficiency and precision led to the development of more sophisticated machinery.

3. The Shift to Automated Filling Solutions

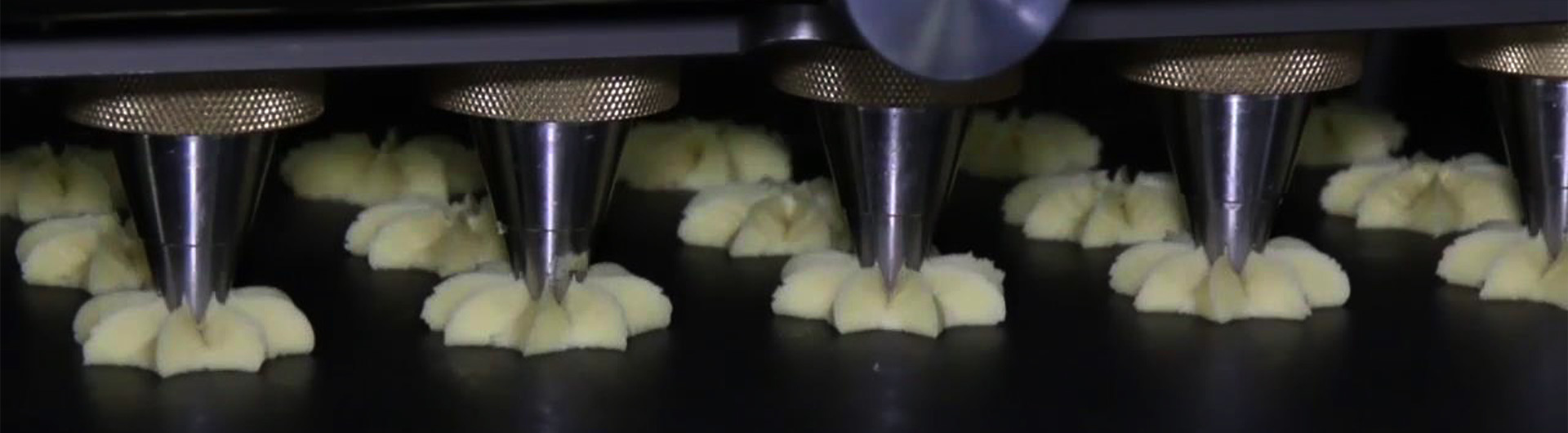

Today, the majority of industries utilize automated filling solutions to enhance their production lines. Automation has not only reduced the likelihood of human error but has also significantly increased output rates. This shift has been driven by the need for higher productivity, better consistency, and optimal resource management.

4. Key Innovations in Filling Machinery

Let’s explore some of the groundbreaking innovations shaping the future of filling machines.

4.1 Advanced Sensor Technology

One of the most significant advancements in filling machine technology is the incorporation of **advanced sensor technology**. These sensors monitor various parameters such as liquid levels, temperature, and viscosity, ensuring that the filling process is accurate and efficient. By providing real-time data, manufacturers can adjust operations on the fly, minimizing waste and optimizing performance.

4.2 AI and Machine Learning in Filling Processes

The integration of **artificial intelligence (AI)** and **machine learning** into filling machines allows for smarter decision-making processes. AI algorithms analyze historical data and adapt operations to enhance efficiency. For instance, predictive maintenance powered by AI can foresee equipment failures before they happen, reducing downtime and repair costs.

4.3 Eco-friendly Filling Solutions

Sustainability is at the forefront of many industries today. **Eco-friendly filling solutions** are gaining traction, with machines designed to minimize waste and reduce energy consumption. Innovations such as biodegradable packaging and energy-efficient motors are helping companies meet their **sustainability goals** while maintaining production quality.

4.4 Flexible and Modular Designs

The demand for varied product sizes and types requires **flexible and modular machine designs**. Modern filling machines can be easily reconfigured to accommodate different products, allowing manufacturers to switch between filling processes without significant downtime. This adaptability is crucial for companies looking to remain competitive in a rapidly changing market.

5. Impact of Innovations on Efficiency and Productivity

The innovations in filling machine technology have led to substantial improvements in overall efficiency and productivity. Automated processes reduce labor costs and minimize errors, while advanced technologies ensure that the filling process is consistent and reliable. The result is a streamlined operation capable of meeting the needs of today's fast-paced market.

6. Regulatory Compliance and Industry Standards

In the filling industry, adhering to regulatory compliance and industry standards is paramount. New technologies not only enhance production efficiency but also ensure that manufacturers meet necessary health and safety guidelines. Advanced filling machines are often designed with built-in compliance features, making it easier for companies to navigate the regulatory landscape.

7. Case Studies: Successful Implementations of New Technologies

Several companies have successfully implemented innovative filling machine technologies, resulting in significant operational improvements.

- **Case Study 1: Beverage Industry** - A major beverage manufacturer upgraded its filling machines to utilize AI-driven predictive maintenance. This shift reduced downtime by 30%, leading to increased production rates and decreased repair costs.

- **Case Study 2: Cosmetics Sector** - A cosmetics company adopted modular filling machines that allowed them to switch between different product lines seamlessly. This flexibility reduced changeover times from hours to minutes, significantly enhancing productivity.

8. Future Trends in Filling Machine Technology

Looking ahead, several trends are expected to shape the future of filling machine technology:

- **Integration of IoT**: The Internet of Things (IoT) will lead to smarter machines connected to a network, providing real-time insights and remote monitoring capabilities.

- **Increased Customization**: As consumer preferences shift, the demand for customized filling solutions will rise, pushing manufacturers to innovate further.

- **Augmented Reality (AR) for Training**: AR could play a pivotal role in training operators, providing immersive experiences on how to manage and troubleshoot filling machines effectively.

9. Frequently Asked Questions (FAQs)

1. What is a filling machine?

A filling machine is a type of equipment used in manufacturing to dispense products into containers. It can handle various liquids, powders, and other materials.

2. How do modern filling machines differ from traditional ones?

Modern filling machines incorporate advanced technologies such as automation, AI, and sensor systems, offering greater efficiency, precision, and flexibility compared to traditional machines.

3. What industries utilize filling machines?

Filling machines are commonly used in various industries, including food and beverage, pharmaceuticals, cosmetics, and chemicals.

4. How can filling machines contribute to sustainability?

Filling machines can promote sustainability through eco-friendly designs, energy-efficient operations, and reduced waste during the filling process.

5. What should companies consider when upgrading their filling machines?

Companies should assess their production needs, regulatory compliance, compatibility with existing systems, and the potential return on investment when upgrading filling machines.

10. Conclusion

The landscape of filling machine technology is continually evolving, driven by innovation and the need for efficiency. As we move beyond traditional methods, it is essential for industry professionals to stay informed about the latest advancements and trends. By embracing these technologies, manufacturers can enhance their operations, meet consumer demands, and contribute to a more sustainable future in the packaging industry.

Previous article

The 23rd Bakery China will be rescheduled to April 27-30, 2021

Since its establishment in 1997, Bakery China has been committed to serving the whole industry chain in the baking industry and is a professional exhibition for bakery products manufacturing and services.

Nowadays, as China's economic development enters the new normal, the development of various industries in China are moving in the direction of intelligence and automation, which is extremely common especially in labor-intensive industries. As we all know, the goal of automation is to achieve the automatic management of processes, without the need for manpower, thereby reducing the cost of labor and greatly improving production capacity.

Five deficiencies and five trends in the development of my country's baking industry

my country's baking industry has emerged in the 1980s and has flourished since the 21st century. The categories are prosperous and the brands are emerging one after another. Common baked goods such as bread, cakes, biscuits and cookies have become popular choices for Chinese people for breakfast. So, what is the development status of my country's baking industry, and what is the future trend? Industry insiders pointed out that there are still "five deficiencies" in my country's baking industry, and the future development will show "five trends".